May 27, 2024 - by Synoptek

The Fourth Industrial Revolution, characterized by significant innovation and growth, also introduces new risks and challenges, particularly in the manufacturing cyber landscape. With the rise of digital technologies and global interconnectivity, cybersecurity in the manufacturing industry is no longer confined to specific aspects of operations or individuals.

Instead, it spreads through various manufacturing levels, affecting every employee, partner, device, equipment, process, and finished product. This high level of complexity exposes potential cyber risks that many manufacturers may be ill-prepared to address.

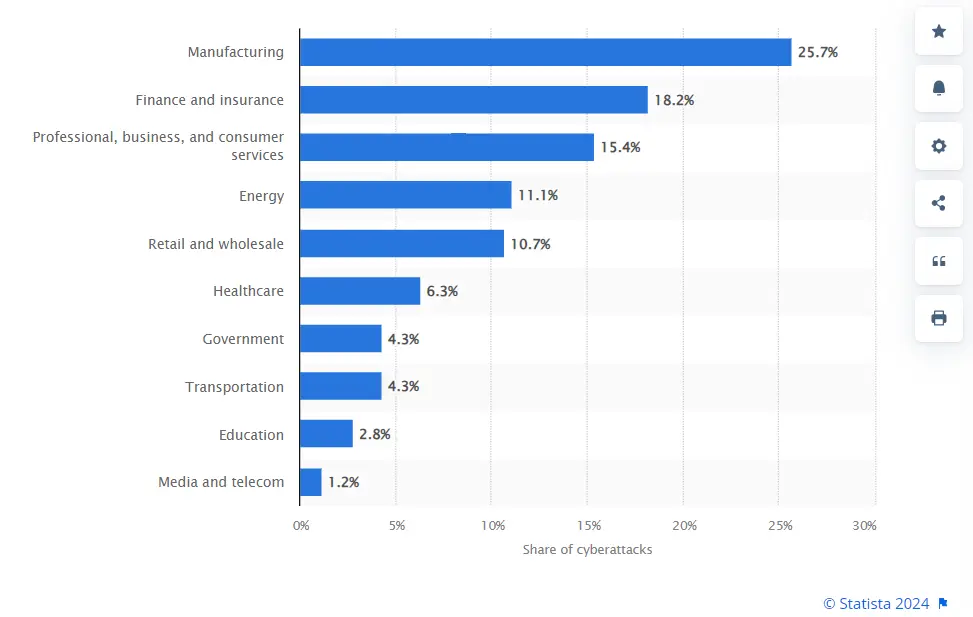

Source: Statista

According to a report by Statista, the manufacturing industry faced the highest share of cyberattacks at 25.7 percent among leading industries globally. In 2023, a multi-billion-dollar semiconductor technology supplier suffered a supply-chain ransomware attack, causing $250 million in lost sales due to disrupted shipments. This incident highlights the increased risk of supply chain attacks in the manufacturing sector, as organizations become more interconnected.

Let’s start by saying that it can be devastating! Cybersecurity breaches disrupt production processes and compromise the integrity and availability of critical systems. Any unauthorized access to sensitive data and intellectual property can lead to financial and reputational losses. Moreover, cyberattacks on smart factories can threaten employee safety, product quality, and overall operational efficiency.

The convergence of operational technology (OT) and information technology (IT) in smart factories creates new attack surfaces for malicious actors to exploit. Every piece of machinery, device, or finished product carries potential cybersecurity risks in the manufacturing ecosystem. In addition to this are several vulnerabilities in interconnected systems that expose critical infrastructure to cyber threats.

Inadequate security measures, such as weak authentication protocols and insufficient network segmentation, can lead to data breaches, intellectual property theft, and operational disruptions.

Here’s a list of cybersecurity risks in manufacturing that can potentially halt production and cause financial losses:

Manufacturers need a comprehensive approach that includes robust security measures, continuous monitoring, regular vulnerability assessments, and employee training to stay cyber-resilient.

However, due to the complex nature of manufacturing environments, securing smart factories involves addressing many issues to prevent unauthorized access. The need is to integrate legacy systems with new technologies, ensure data security across interconnected devices, manage the risks associated with IoT devices, and establish robust access controls.

As cyber threats targeting smart factories continue to evolve, so do the challenges in smart factory cybersecurity:

With constant vigilance, proactive measures, and ongoing investment in cybersecurity solutions, manufacturers can mitigate these risks effectively and safeguard critical operations and intellectual property.

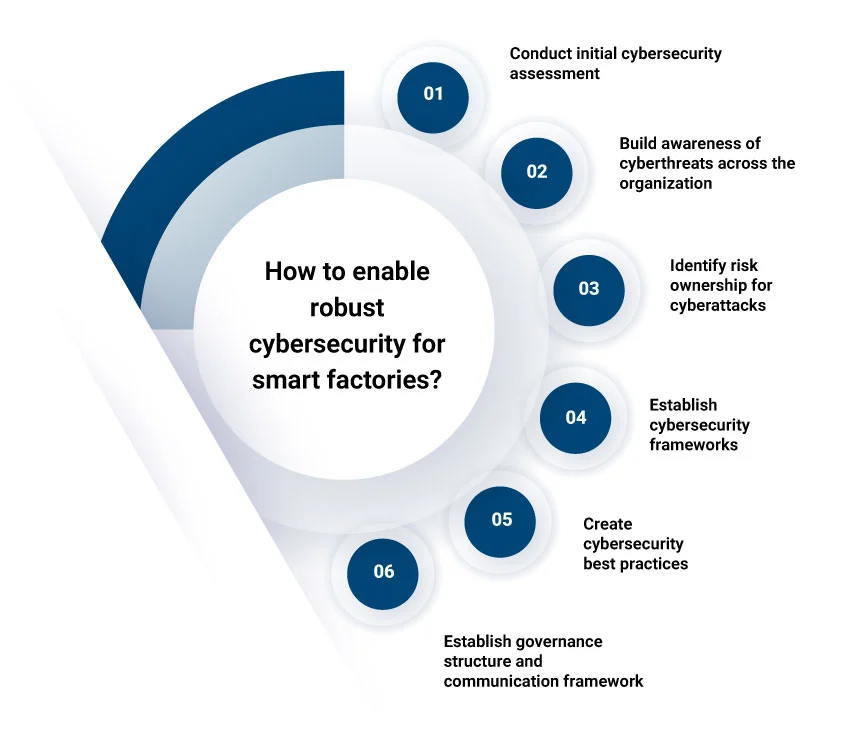

Listed below are the key steps for building a strong cybersecurity strategy in smart factories, safeguarding critical operations, data, and assets from cyber threats, and ensuring the continuity and security of manufacturing processes:

Has your organization performed this in the past year? If not, prioritize this, as new vulnerabilities come with every use case. Evaluate your organization’s current cybersecurity state to identify strengths, weaknesses, and areas for improvement. Try to include business networks, IP protection, control systems, connected products, vendors, suppliers, and partner ecosystems. This can help understand the current level of cybersecurity risk and develop a roadmap for enhancing existing cybersecurity posture.

This program should consider both IT (information technology) and OT (operational technology) teams to ensure seamless collaboration. It should ideally cover all systems and devices within the smart factory. A formal governance program can help establish clear roles, responsibilities, and policies for managing cyber threats.

Like for example, in the US, the National Institute of Standards and Technology (NIST) has released a cybersecurity practice guide for the manufacturing sector. This National Cybersecurity Center of Excellence (NCCoE) practice guide provides example solutions and guidance for using commercial technologies to detect and prevent unauthorized software installation, protect ICS networks, monitor network changes, identify unauthorized system access, continuously monitor network traffic, and leverage malware tools to enhance cybersecurity across organizations.

Gather your cybersecurity maturity assessment results to build a roadmap. Prioritize cybersecurity efforts based on the smart factory’s risk profiles of different assets, systems, and devices. This can help ensure that optimal resources are allocated effectively to address the most significant risks first.

Incorporate necessary security measures at the outset of smart factory projects. Establish essential controls to implement secure network segmentation models and deploy passive monitoring solutions with minimal disruption risk. Ensure secure remote access, enhance privileged access management, and establish backup procedures for critical systems.

In a connected smart factory environment, the extensive range of cyber threats and vulnerabilities underscores the importance of cybersecurity in building a resilient organization. All employees should be empowered as front-line defenders of the company’s security, equipped with the necessary awareness and tools to be cyber-resilient experts.

By implementing effective cyber risk management for smart factory initiatives, manufacturers can harness the benefits of the Fourth Industrial Revolution while mitigating the risk of future cyberattacks.

Connect with Synoptek experts to help you detect threats and safeguard your organization in a timely manner!