| Customer: A manufacturer of prime quality steel products | Profile: The client produces prime quality steel products from recycled scrap steel for the mining, construction, automotive, and engineering industries. |

| Industry: Mining and Metals | |

| Services: Dynamics QA |

Business Need

The steel manufacturer was using Dynamics 365 Finance and Operations to run day-to-day operations of their business. Because the manufacturer was part of a larger enterprise, with the segregation of the companies, their production environment was duplicated into a new instance. This instance still contained all customizations that were mainly focused on parent company processes. As a result, such customizations needed to be removed for other entities/child companies, in order to make their processes simple. To ensure the ERP solution worked optimally after removing customizations, thorough manual testing of different modules, which was repetitive in nature needed to be done.

The manufacturer wanted to engage with a provider who could analyze various processes that were executed within D365F&O and create automated testing scenarios that could be utilized at every platform upgrade to significantly reduce manual verification efforts. This would enable users to leverage capabilities of the latest version of their Dynamics solution.

Since the manufacturer is one of the clients of a Microsoft VAR Synoptek acquired in 2019, they reached out to Synoptek to fulfil this Dynamics QA requirement.

Solution and Approach

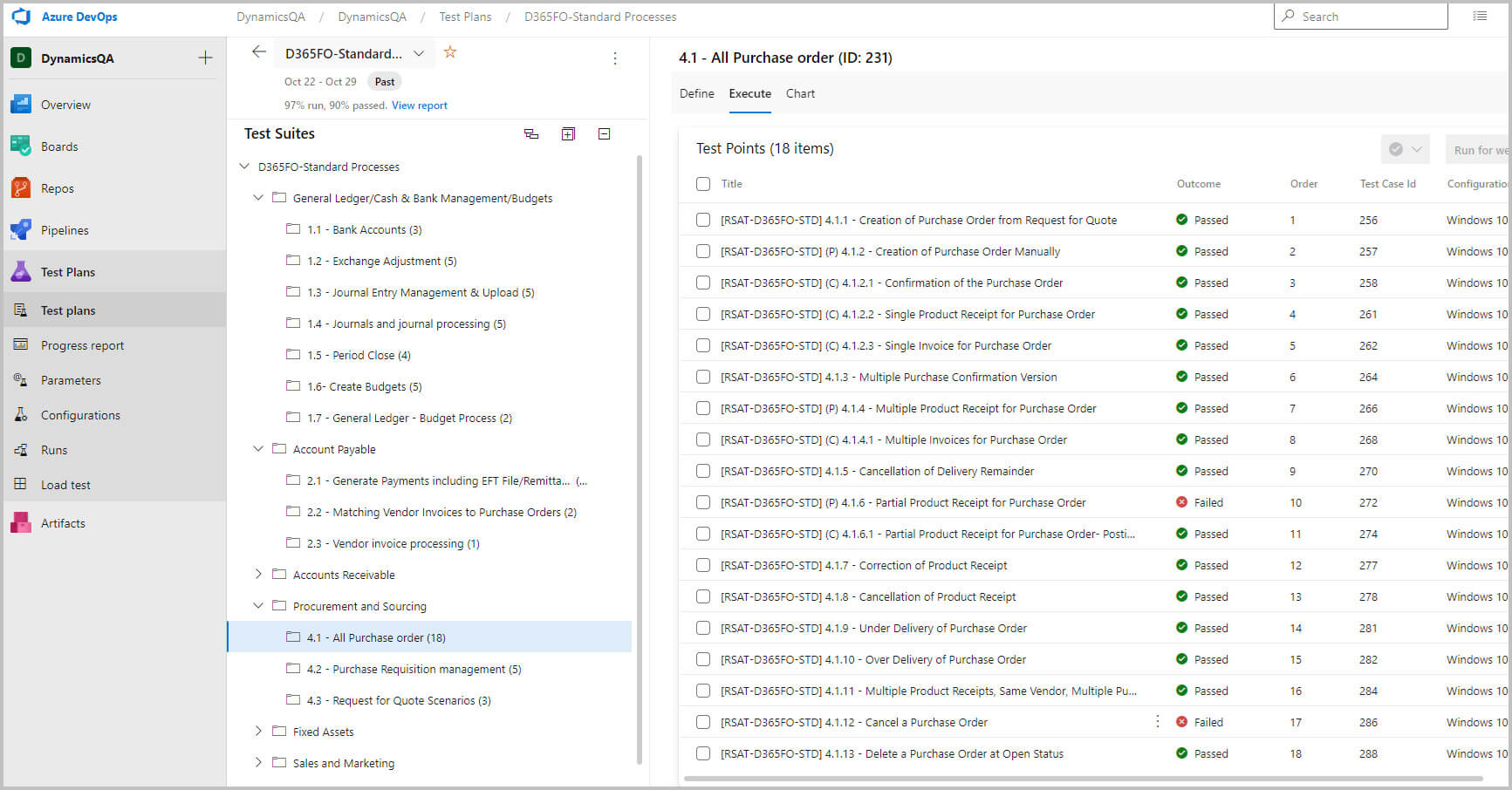

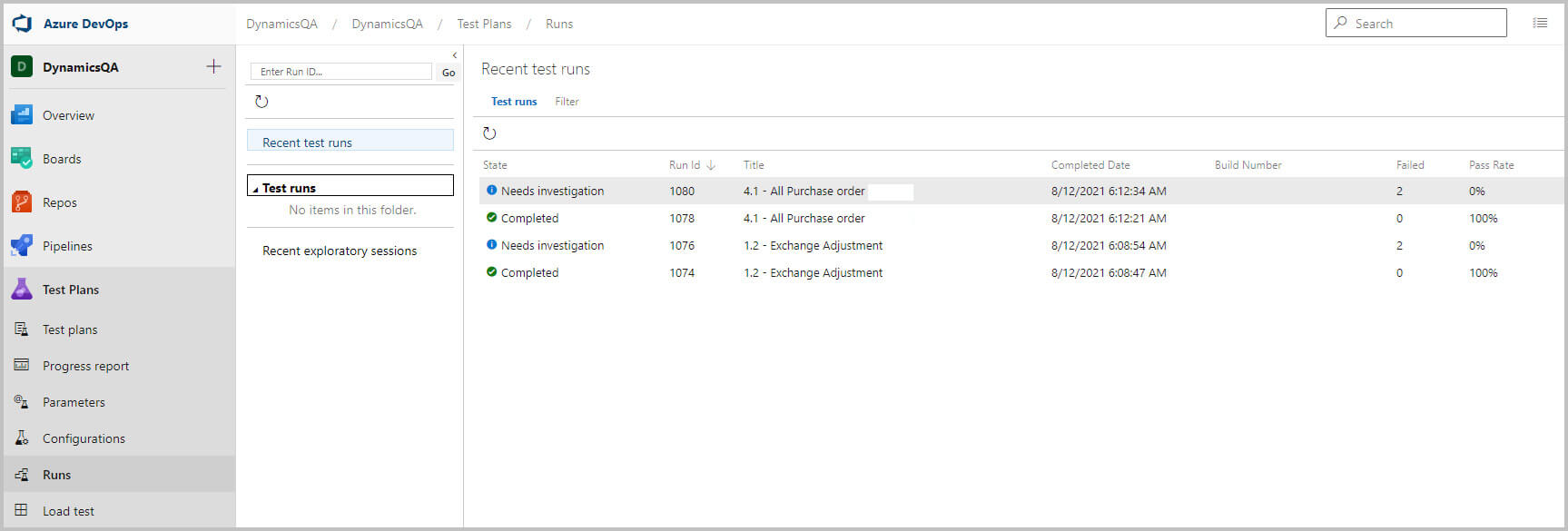

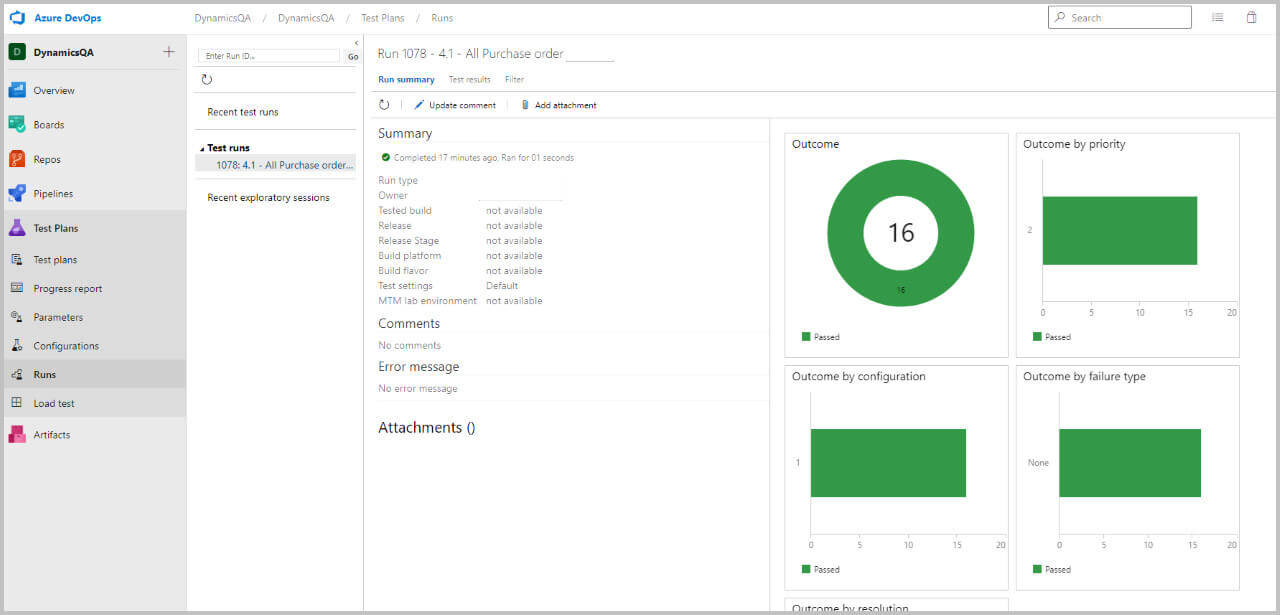

To meet the manufacturer’s requirement, Synoptek, a Microsoft Gold Partner, adopted RSAT – Microsoft’s automation tool for D365F&O testing – to automate many of the D365F&O processes. The tool not only helped us in reducing the time and cost of testing, it also allowed functional users to record business tasks and then convert the recordings into a suite of automated tests – without having to write source code. Since the tool is fully integrated with Microsoft Azure DevOps, it resulted in seamless test execution, reporting, and investigation.

The Synoptek QA team performed the following activities:

- Listed down 100 pre-recorded scripts as provided by the manufacturer which had basic end-to-end flow of different AX and D365 FO processes.

Two scenarios listed below:

Purchase Order

- Create Purchase Order > Add Purchase Order line with quantity, Discount, Unit Amount > Validate Net amount > Save the Purchase Order.

- Open the Purchase Order as created above > Submit for approval to confirm > Reassign to Admin user > Approve the workflow > Confirm the Purchase Order > Validate the line-item number, quantity, net amount, etc. in Purchase Order confirmation journal.

- Open the Purchase Order as created above > Post the product receipt and validate the line-item number, unit amount, net amount, etc.

- Open the Purchase Order as created above and validate the status of purchase order as Received > Post the invoice and validate the line-item number, unit amount, net amount, etc.

Sales Order

- Create New Sales order > add line-item with quantity, Discount, Unit Amount > Validate Net amount > Save the Sales Order > Confirm the Sales Order > Validate details in Sales Order confirmation journal > Pick and post the packing slip and validate the details > Post the invoice and validate the details in invoice journal > Validate the Sales Order status.

- Understood the complete end-to-end flow of each scenario and identified fields for which validation was required.

- Saved and uploaded the recoded script on LCS, fetched and added the script to the test plan on DevOps, and loaded the script on RSAT to generate the input parameter file.

- Changed the value of each parameter in the file according to the business scenario and ran the script from RSAT.

- Uploaded the latest files to Azure DevOps from RSAT after successful execution and verified the result on DevOps.

- Executed test scenarios again using RSAT, whenever required, and re-worked on test scripts when new changes were made in the processes.

- Provided training material for using RSAT and made sure the manufacturer had complete understanding of how to perform the RSAT steps.

Business Benefits

Synotpek’s Dynamics QA Services enabled the manufacturer to achieve several business benefits:

- Allowed the manufacturer to test an exhaustive list of scenarios in contrast to limited scenario testing by their in-house functional team

- Automated end-to-end D365F&O scenarios and helped in minimizing manual verification efforts by 40 to 50%

- Made it easy for the manufacturer to identify at what stage a script fails and the reason behind it

- Enabled scripts developed for one entity to be reused across multiple entities, thus saving them substantial time in testing by completing the project in 5 months

- Ensured that the MODs were properly analyzed, migrated, or removed according to customer needs, assuring data integrity

- Removed over 115 customizations with zero data issues, improving the functionality and performance of D365F&O platform while ensuring optimum results and ROI from their Dynamics investment