October 18, 2024 - by Synoptek

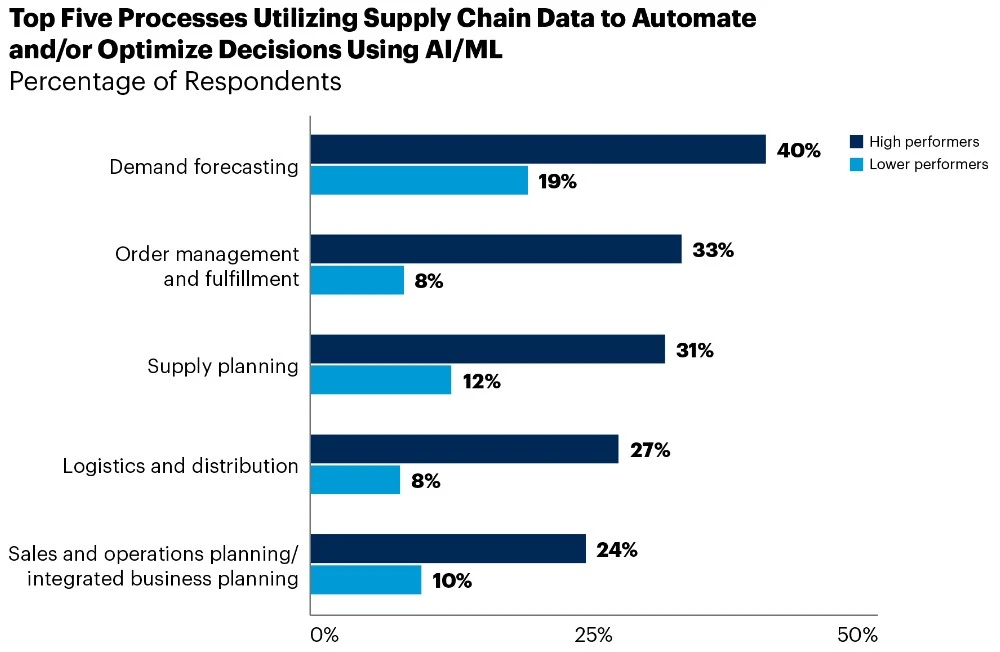

According to a Gartner study, top supply chain organizations use Artificial Intelligence (AI) to optimize processes at more than twice the rate of low-performing peers. AI allows them to adapt to changes in economic values, foster sustainable growth, harness digital assets’ potential to enhance productivity, and revitalize the workforce and network of people.

Unlocking the full potential of supply chains has long been a goal for businesses that seek efficiency, resilience, and sustainability. So, how exactly does AI help achieve all this? Let’s find out!

Modern supply chains are highly entangled and expansive, making it difficult for manufacturers to maintain end-to-end oversight of materials and goods moving in and out of their facilities. AI offers numerous capabilities that help to swiftly analyze large data sets and shed light on the inner workings of even the most complex logistics networks.

Businesses in the supply chain have been increasingly deploying artificial intelligence (AI) for demand planning, process standardization, last-mile delivery optimization, etc. Even in the relatively nascent stage, AI adoption is as high as 62%, according to an Ernst and Young study. In the last year, Generative AI has displaced AI, empowering businesses to pursue innovation and strengthen supply chains through large language models.

In an era when supply chain disruptions have become increasingly complex, GenAI helps companies solve these modern supply chain management challenges for a competitive edge, forecasting trends and optimizing operations.

This technology is being embedded in almost every facet of the supply chain, and new use cases continue to emerge. AI will undoubtedly be an integral component of all supply chain management systems in the future.

Source: Gartner

Organizations across supply chain networks can benefit significantly by embracing the latest advancements in artificial intelligence technology. If you are looking to deploy AI and be at the forefront of innovation, here’s looking at a few use cases where this technology offers exceptional impact:

In the realm of risk management, Generative AI enables companies to have natural language conversations with large language models and tweak their strategies based on the suggestions received. For instance, a drug manufacturer can run what-if scenarios on getting specific chemicals for its products and assess the impact of global shocks on daily operations. It can also receive suggestions on possible courses of action if things go awry.

Generative AI offers far-reaching benefits in logistics, enabling companies to optimize picking routes dynamically. Companies can choose routes based on fuel availability, weather, or traffic conditions and even prioritize deliveries based on demand. The technology can also help reduce operational costs through optimized space and material handling.

Supply chain organizations can use chatbots powered by GenAI to negotiate cost and purchasing terms with vendors in a shorter time frame. The technology also presents an opportunity to improve supplier relationships and management, with recommendations for next steps. These tools can quickly extract information from large contracts and help supplier teams prepare better for upcoming renewals.

The buzz around AI has engulfed the business landscape in a way no one had ever imagined. While AI plays a huge role in driving greater supply chain efficiency and reducing operational costs, it also enables high productivity levels to sustain business momentum.

However, despite GenAI’s far-reaching benefits, implementation is limited when rushed or poorly integrated across the supply chain network. Since GenAI tools are only as powerful as their input data, it is essential to ensure the quality and availability of data from the very beginning.

To ensure a successful implementation, strengthen governance, ensure transparency, and comply with necessary ethical and legal considerations, you must engage with a qualified and competent Artificial Intelligence consulting partner.

Contact us to get started on your AI journey today!